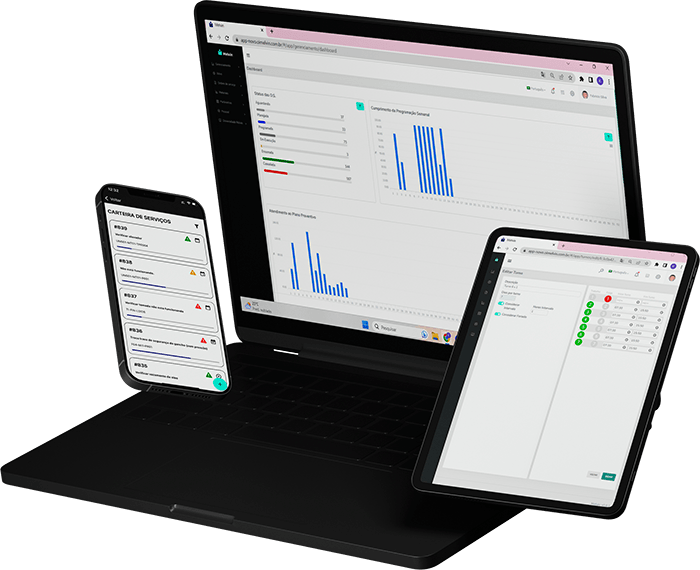

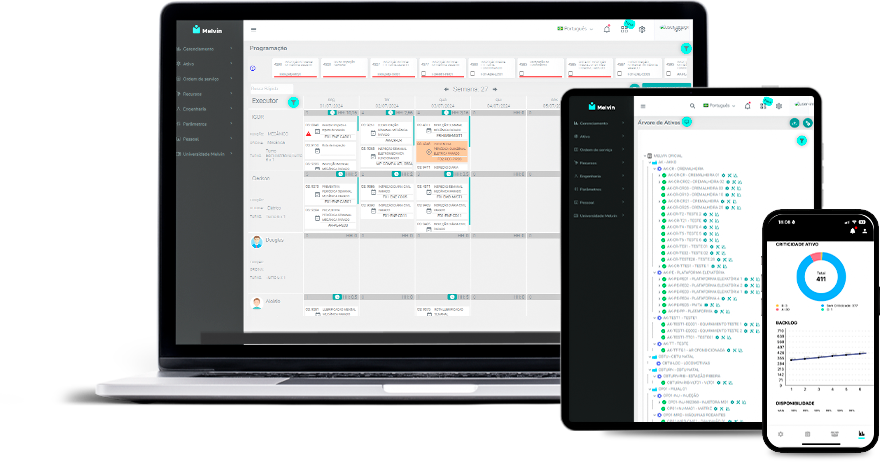

The Maintenance Software that intuitively leads the user to manage maintenance that really works!

Simple, practical, and intuitive

Be surprised and see in practice how it’s possible to implement the PCM routine in just 2 weeks!

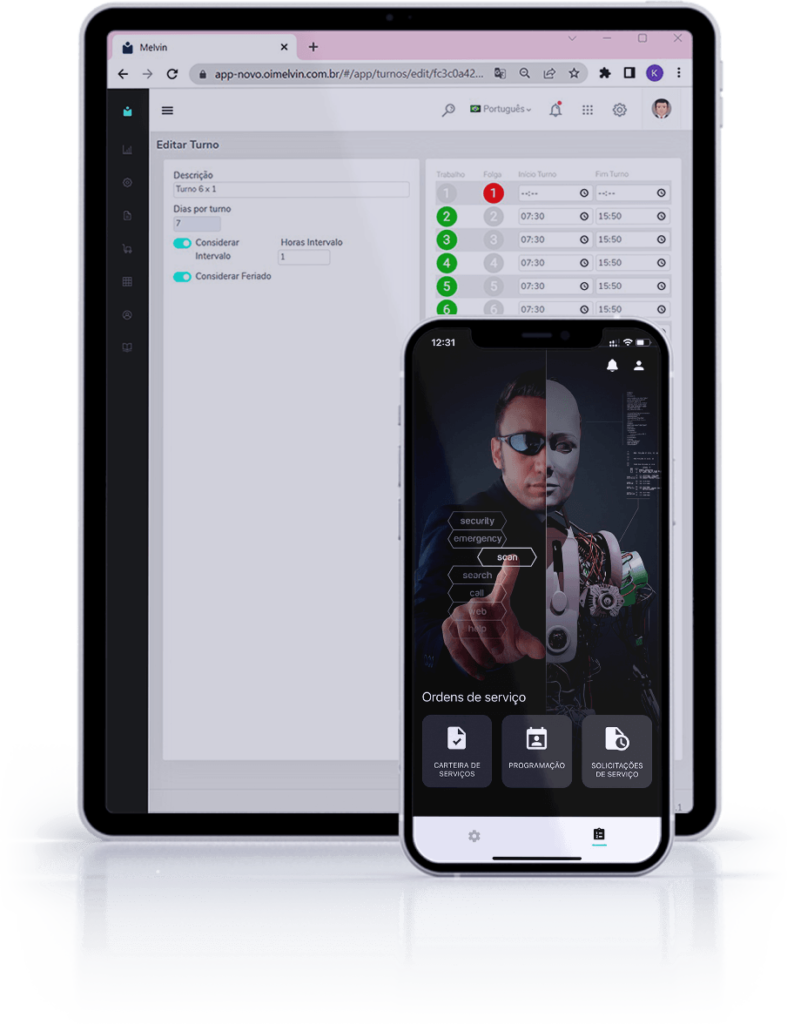

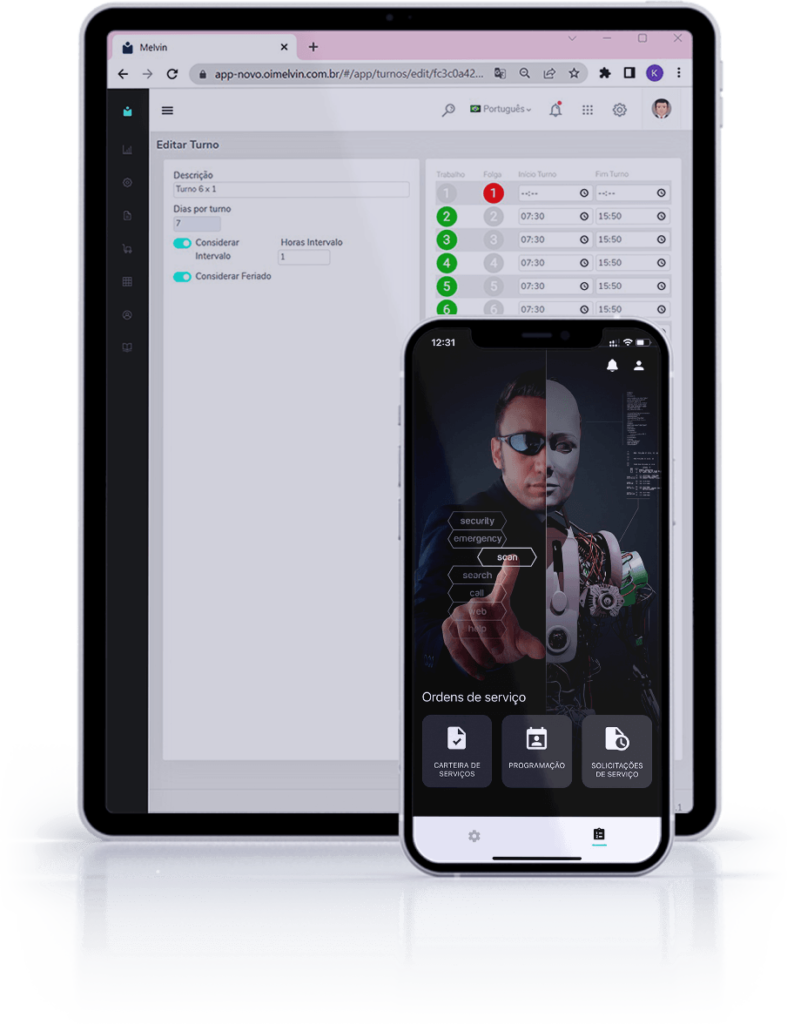

Integrations

Sensors IoT Melvin

Predictive Maintenance that really works!

Vibration, Temperature, Inclination and 4 to 20 mA

How it works

The rotating components of

Equipment can show signs of failure through vibration and temperature.

From these quantities it is possible to know when the failure will occur and what the diagnosis of this failure is.

With this, we are anticipating

production stoppage, due to equipment stoppage.

In short, we are automating fault identification in real time.

Test for

You will have the same experience as a customer who already has Melvin sensors installed. Through a virtual sensor that replicates real vibration and temperature data, you will be able to see in the Melvin monitoring module,

Predictive Maintenance working fully.

Sensor differences IoT

Quick and easy installation: The sensors are magnetic and fixed by magnet. The Gateway can use network ethernet, wi-fi or 4G.

Battery life: Considering one collection per minute, the estimated duration is 10 years.

Variable speed monitoring: one sensor is connected to the frequency inverter and another collects vibration and temperature data.

Alarms by frequency bands: configuration of spectral bands for monitoring the frequency of bearing failures.

Direct-to-user insights: the alarm is sent by notification in the App and by email.

2022 – www.oimelvin.com – Politica de privacidade